Roland DGA talked to Shawn Sims, Director of NOTLabs about his latest milling project

NOTLabs, the production arm of inspiration site, NOTCOT, has completed yet another amazing 3D milling project that we’re excited to share. Shawn Sims, who was responsible for milling Andrew Bell’s skull design and the Jurassic Park Lego planters has taken milling to the next level with his latest project for David Kind Eyewear.

NOTLabs initially intended to create a shelf/swing design with a sharp, geometric 3D pattern. However, after Dave Barton, founder of David Kind Eyewear saw what NOTLabs was milling, he asked them to turn the design into an eyewear display for his David Kind store in Los Angeles. NOTLabs set about milling a new POP display version of the design on the Roland DG MDX-540S in multiple wood materials to complement the different styles of eyewear.

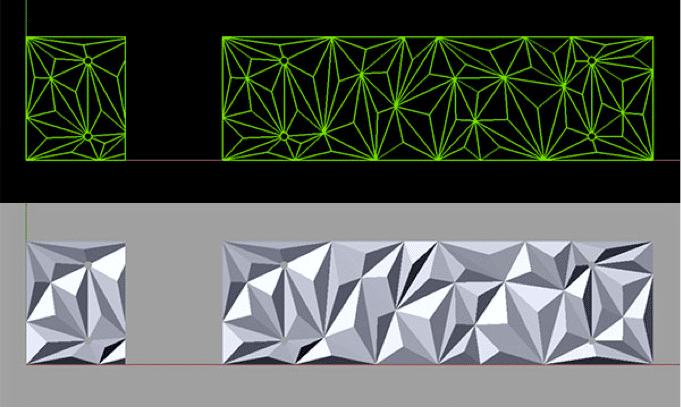

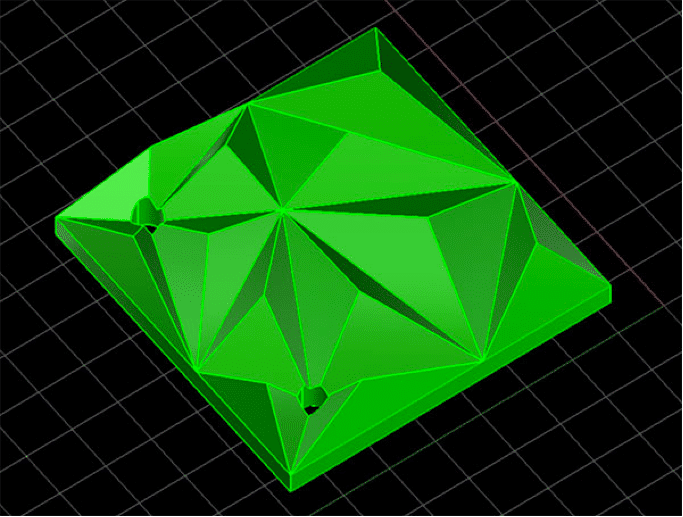

The initial 3D artwork and the David Kind stand adaptation – an original milling concept with complex geographical shapes, perfectly juxtaposed against the organic wood material it would be milled out of.

Shawn told us about the overall difficulty of this project and the challenges he faced milling this tight geometrical pattern and how the MDX-540S simplified this complicated process.

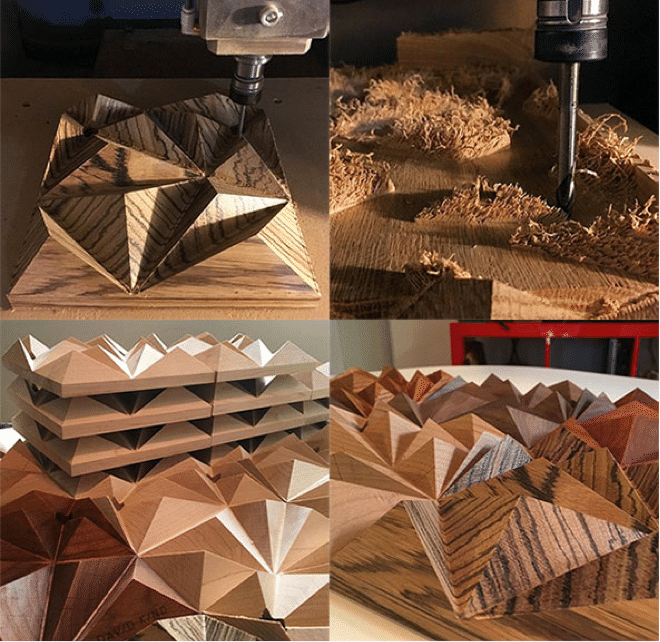

“The walnut and zebrawood stands were made in-house on the Roland DG machine and there were a few challenges along the way, but we are thrilled with how the stands came out using the Roland DG 540S. It can be tough to get sharp edges when milling wood but the Roland DG makes the process easier.”

Various views of the milling process and completed stand designs – the zebrawood version (top left) required a slower milling process but as you can see, the results were terrific.

Shawn used mostly maple and walnut on this project but he also wanted to add some rare wood and found some exotic zebrawood for a special stand. He milled the zebrawood really slowly to avoid any chipping and described the smoothness right off the mill as being “stunning”.

“We have milled a lot of hardwood before, but every piece can behave differently. We slowed the machine way down for the Zebrawood. You need to pay close attention to the grain and how the CNC bit is removing material.”

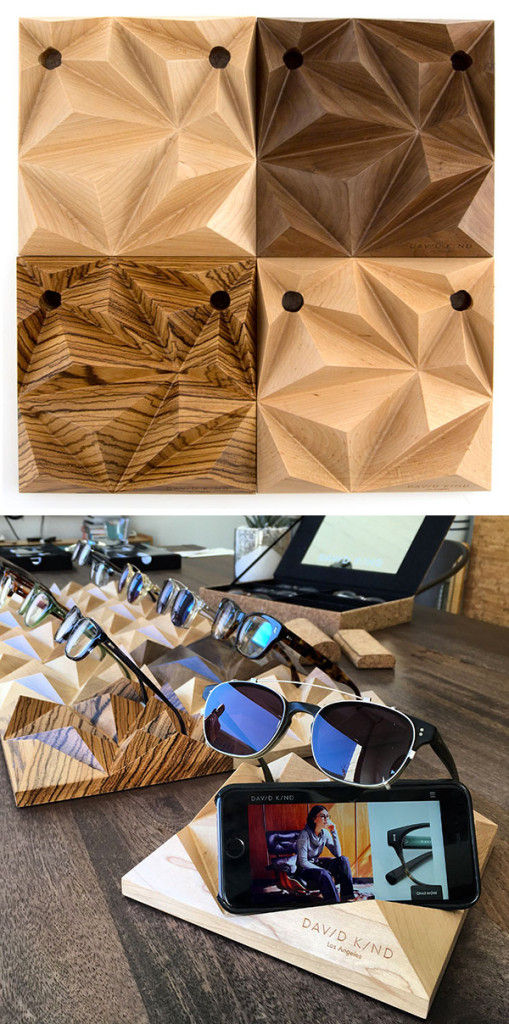

Views of the three different wood versions and the finished product as seen in the David Kind store in Los Angeles, complete with laser-etched logo.

The stands were sanded and finished off with the addition of felt to the underside and a David Kind laser etched logo to their fronts. As you can see from the image above, the finished stands are truly impressive – each one displaying the unique qualities of the wood it was milled from and creating a true one-of-a-kind display.

This was an exciting project to see evolve and come to fruition, and we can’t wait to see what Shawn and NOTLabs do next. We asked him what he has in-store for the future.

“We have a few exciting projects currently in the works using the Roland DG and we look forward to sharing them in early 2016…. We are always experimenting with new materials and processes – non-ferrous metals are probably our next adventure.”

Go to www.notlabs.com to see this project and other adventures in milling.

- Check out the features and milling possibilities of the Roland DG MDX-540 Benchtop Milling Machine and see the many prototyping, snap fit part, molding and custom jewelry applications.